- Devashish Patwardhan

- Dec 6, 2023

- Industry

An industrial panel PC is a computer. Built-in the flat-screen and has a multi-touch display. It allows your entire system to be placed around the areas where the displays are to be mounted. They are used mostly in the process of industry automation, machinery control, process control and manufacturing applications.

The display screens in industrial panel PCs are made with a rugged finish to deal with industrial environments, making them better than those of conventional PCs. The purpose of it is to replace the traditional control panels and bring in user-friendly accessibility for the newer machines, especially in the manufacturing sector.

Industrial panel PCs help in improving the efficiency and productivity of manufacturing operations. This blog will help you understand all core applications of industrial panel computer vision in the manufacturing industry.

Harness the power of Industrial Panel PCs. Elevate productivity – Request a quote now

Exploring The Industrial Panel PC Applications in Manufacturing

Industrial Panel PCs are widely used in the manufacturing sector to help ease the overall operations associated with diverse applications of industrial panel pc for manufacturing industry. Here’s a glimpse at some of those applications for you to understand the workings of industrial panel PCs.

1. Automotive Manufacturing

Industrial panel PC is used in the automotive manufacturing sector for establishing proper quality control at all stages involved in the process. Following that, every part being installed in the car must be assessed for quality and functionality. Thus, such inspections are also handled through these industrial PCs.

May it be diagnosing the vehicle sensors or features or controlling the robotic assembly line, the industrial panel PCs for the automotive industry are considered necessary equipment or tools. Apart from that, it also offers human/machine interfaces or HMI panels to improve safety in automotive manufacturing. Resource management and production scheduling are further add-ons to the service benefits of this panel PCs.

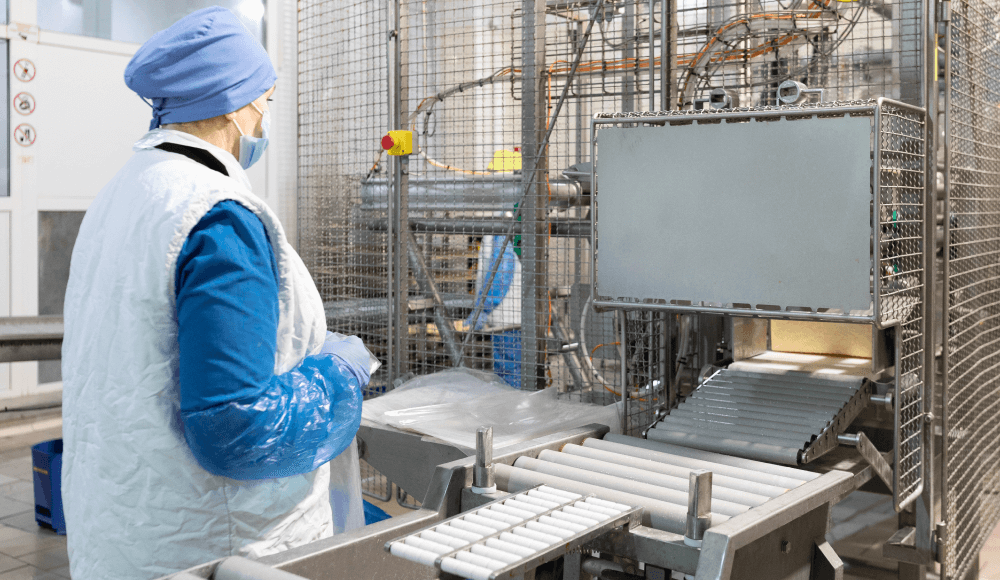

2. Food and Beverage Processing

Pixelwise Technology LLP. brings to you the best-in-class industrial panel PCs that are capable of handling applications across diverse manufacturing industries. Food and beverage processing is one of those industries that leverages the benefit of these PCs to streamline their operations.

It helps you with batch and recipe management for automated food production operations. The practices being implemented in the food and beverage sector should be compliant with the food safety norms. Hence, the industrial panel PCs ensure the same! Moreover, these panel PCs also monitor the moisture or humidity level in food storage aspects and control the same as well. Finally, you can avail better supply chain and inventory management.

3. Pharmaceutical Manufacturing

While being used in pharmaceutical manufacturing, industrial panel PCs or touch computers are used for better quality control while handline medicine formulations, raw materials, and finished products. These computers help keep track of the medicine specifications being met during the manufacturing process.

While being used in pharmaceutical manufacturing, industrial panel PCs or touch computers are used for better quality control while handline medicine formulations, raw materials, and finished products. These computers help keep track of the medicine specifications being met during the manufacturing process.

Moreover, the industrial panel PCs also help the key players adopt GMP (Good Manufacturing Practices). Apart from that, the cleanliness and hygiene of medical rooms are also monitored through these PCs. All pharmaceutical products need proper serialisation and batch tracking, which these industrial PCs can handle easily.

4. Electronics Manufacturing

The PCB (Printed Circuit Board) boards manufactured at the dedicated facilities will need proper quality control, as major electronic applications depend on them. Using the industrial panel PCs, the assembly of PCBs can be monitored efficiently. In case of any faults in an appliance or electrical assembly, these PCs can be easily used for component tracking or traceability.

Semiconductor manufacturing also needs some process control within the facilities. Therefore, the industry is switching to adopting industrial panel PCs to ensure better process control for diverse electronics applications.

5. Aerospace and Defense Manufacturing

Industrial panel PCs are highly efficient in terms of handling flight control, communication and aircraft maintenance. The aerospace and defence sector promotes the use of industrial panel PCs for industrial use for flight control systems. This helps in processing the received data and sending it to the pilots for them to take the necessary action.

Beyond that, the aerospace and defence sector uses industrial panel PCs for monitoring the CNC machines that make precision aircraft parts. Moreover, it ensures the manufacturing process aligns with the aerospace quality parameters. The configuration approaches for all the complex assemblies are handled through industrial computers, which also include QA and material testing.

6. Chemical Processing

The industrial panel PCs are built with explosion-proof ratings for being used in hazardous areas, even when there are chemicals or flammable vapours present. They help with embedding control over the distillation process or chemical reactors. Moreover, this helps with tracking and managing the inventory where chemical products or raw materials are stored.

Moreover, industrial computers are also used to ensure that your practices align with the chemical safety regulations or not. In short, industrial PCs can be purged in order to make them even safer for being used in highly volatile environments.

7. Plastics and Rubber Manufacturing

In the plastics and rubber manufacturing sector, industrial computers are used mostly for controlling pressure and temperature changes precisely. Moreover, it also extends control for the moulding and extrusion machines involved in producing rubber or plastic. Not only that, but all the moulded parts are also monitored for optimal quality using these panel PCs.

In the plastics and rubber manufacturing sector, industrial computers are used mostly for controlling pressure and temperature changes precisely. Moreover, it also extends control for the moulding and extrusion machines involved in producing rubber or plastic. Not only that, but all the moulded parts are also monitored for optimal quality using these panel PCs.

The injection moulding machines used in rubber or plastics manufacturing facilities require a substantial amount of energy to run seamlessly. Using the industrial touch screen PC, in this case, will help you manage energy consumption and look after reducing operating expenses.

8. Textile Manufacturing

In the textile industry, where intelligent production is of utmost importance, industrial panel PCs are used for recording the operation as well as processing data. It makes use of standard, interactive, temporary and personalised reports to obtain specific information. It helps meet your energy-saving requirements, downtime reduction, data collection and others.

The use of industrial panel PCs in the textile sector helps make the entire weaving factory intelligent. And that’s possible because of the process control that this upgraded system has to offer. It helps with forecasting, scheduling and planning the entire work by analysing the manpower, available material and other such factors. Moreover, it also monitored the colour consistency and textile quality, alongside managing the inventory of raw materials and finished goods.

9. Metal Fabrication and Machining

If your industrial facility deals mostly with metal shaping and cutting applications, then the industrial panel PCs can help you with optimal CNC machine control aspects. Apart from that, it also monitors the metalworking coolants and fluids to ensure uninterrupted operations. Beyond that, wear & tear of the tool will also be tracked, and maintenance efforts will be executed timely.

While producing the metal parts, quality control is of utmost importance to ensure the associated applications turn out to be proficient. Therefore, industrial PCs are the new-age smart implementations to the metal manufacturing facilities for implementing quality control. Following that, industrial panel PCs help the metal fabrication and machining industry with equipment monitoring, data collection, process visualisation and others.

10. Renewable Energy Manufacturing

The renewable energy manufacturing sector has also adopted the use of the latest technology solutions in their practices. Industrial panel PCs are offering immense control to the key players of the industry upon production processes associated with wind turbine parts or solar panels. Moreover, it also helps with collecting data with respect to energy efficiency.

It helps you determine if your production or manufacturing practices align with the official renewable energy regulatory standards. Not only that, but industrial PCs can help set maintenance schedules for dedicated renewable energy components.

Harness the power of Industrial Panel PCs. Elevate productivity – Request a quote now

Conclusion

These are the ten industries that have leveraged the applications of industrial panel PCs in their operations. It is the future of industrial or factory automation that is presented as the epitome of technology. The production facilities are being refined with better operations through automated processes.

These panel PCs aren’t just helping industries or factories scale with their productivity but also providing them with a long-term and cost-efficient solution. If you seek digital transformation for your industrial applications, then you must install an industrial panel PC in your facility.

So, if you want to get one installed in your facility or want to learn more about the same, contact us today, and we shall attend to all your questions or queries regarding its industry-wise functionalities.

Devashish Patwardhan

Devashish Patwardhan is a dedicated and highly skilled manager at Pixelwise Technology LLP, where he excels in providing cutting-edge inspection and automation solutions for the printing, packaging, and pharmaceutical sectors. With over seven years of hands-on experience in industrial automation and vision inspection, Devashish continuously develops innovative, cost-effective systems that meet his clients' diverse needs. A graduate of the esteemed Pune Institute of Computer Technology & Electronic Research, he holds a degree in Electronics Engineering (2017) and is known for his strong engineering background. Devashish's passion for utilising his technical expertise and creative problem-solving skills drives him to become a top technocrat entrepreneur.